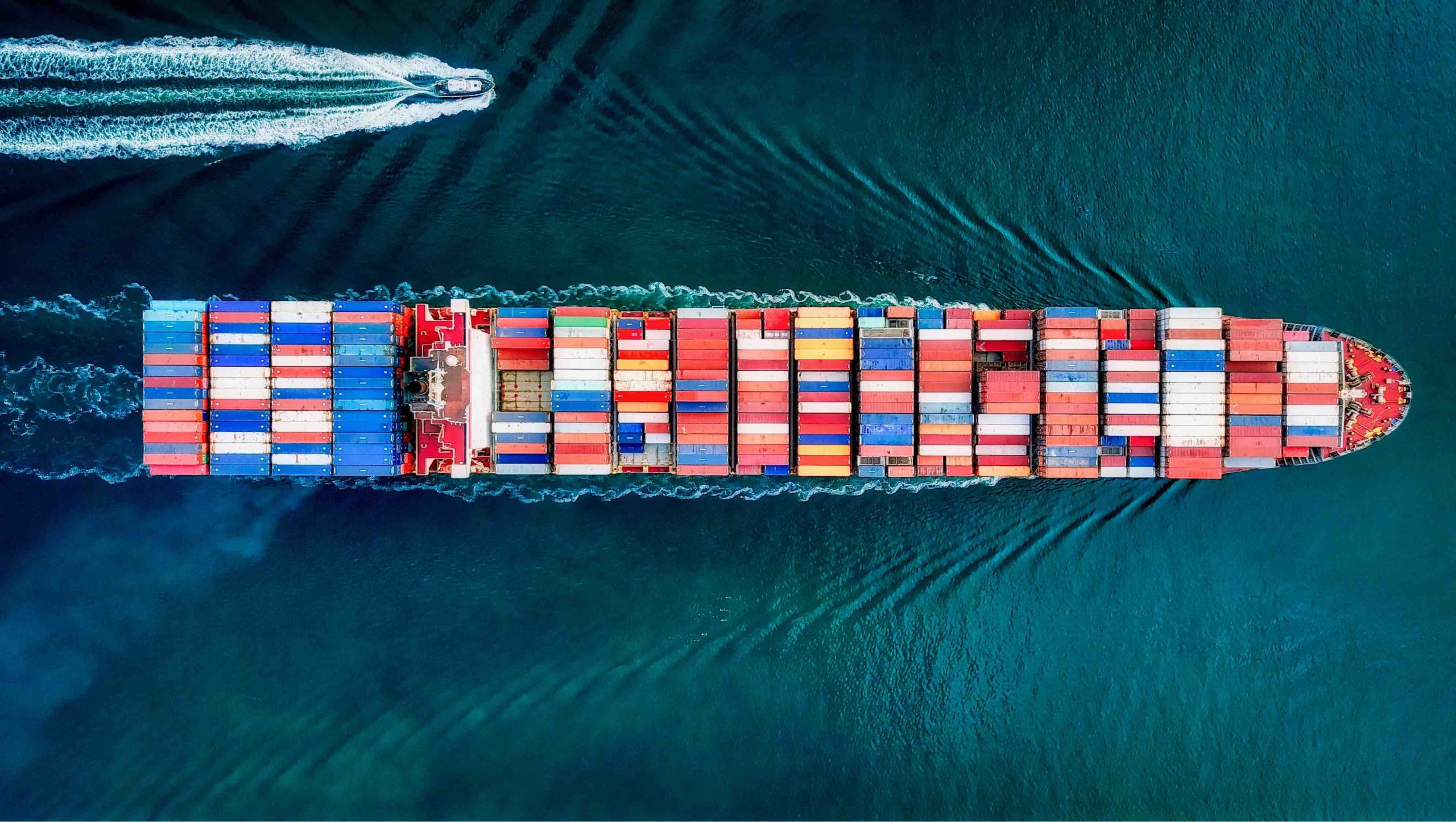

Cargo ships are a unique kind of vessel. The design and purpose of the ships seems simple from the outside, but a good look at the inside reveals a lot of interconnected design and more moving parts than you might have expected.

One example of these complex systems is the ventilation. While it is important to have good airflow on any boat, it is especially important for one that has below-deck operations and accommodations. For ships that are built for long-term trips, such as cargo boats, they often contain chemicals and perishables that have to be stored properly and require adequate ventilation. To better understand the ventilation requirements of cargo ships, there are a few guidelines that you need to remember.

The Difference Between Kinds of Cargo

One of the quickest ways to understanding cargo ship ventilation is to understand the kinds of cargo that they can carry. These things can be varied, as you have likely seen when working around the water, but the cargo on most ships can be broken down into two main types:

- Hygroscopic Cargo – This type of cargo is a product that contains natural moisture. This may include grains or other types of agricultural products. Depending on the environment and atmosphere that they are being moved from, in, or to, this type of cargo can absorb or release moisture during travel and may require additional ventilation to keep the products fresh.

- Non-Hygroscopic – This type of cargo does not carry additional natural moisture and is usually solid, non-perishable products. However, these products may be susceptible to humidity and temperature changes, which may mean stricter storage and ventilation requirements and guidelines.

Preventing Cargo Sweat

For cargo ships carrying non-hygroscopic products, ship sweat, or cargo sweat, can result in a lot of damage. Vessels need to be able to adjust to varying humidity and temperatures as they travel, otherwise, the vessel can become saturated and damage the cargo. Understanding how ships sweat is critical for arriving safely at a destination.

Monitor the Inside and Outside Temperatures

To keep cargo from being impacted by moisture, you need to ensure that the humidity and temperature is being monitored both inside the ship and outside. Thermometers and hygrometers should be installed in both areas and routinely monitored.

Ventilate the Air

When it comes to ventilating the cargo, many people mistakenly believe that you can just set the ventilation system and let it do its work, but that is not the case. This can actually cause more damage in the long-term. Ventilation should only be used when the humidity exceeds the recommended guidelines of the cargo that is being carried. Temperature and humidity discretions are most common at night, so it is vital to monitor levels constantly..

Contact an Experienced Maritime Law Attorney Today

Clearly, the ventilation of a ship is much more complicated than one might believe. This also means that there is more potential for accidents and injuries involving workers on a cargo ship. If you are a cargo ship worker that has been injured in an accident, whether due to the ventilation system or something else, you may be entitled to compensation for your injuries. The attorneys at Kolodny Law Firm can advise you of your rights and ensure you get the compensation to which you are entitled. Contact us today to schedule a consultation.